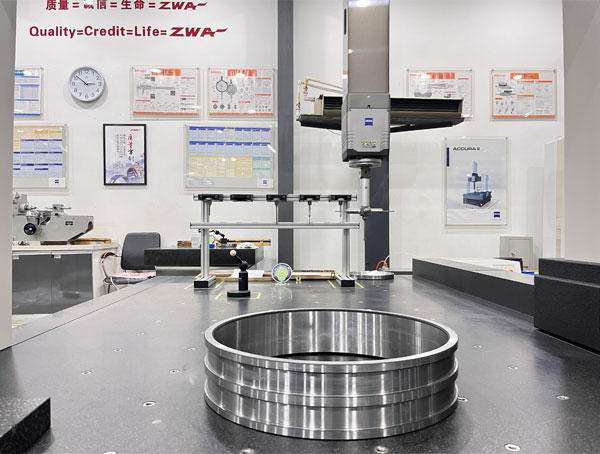

At ZWA bearings, quality is our first priority, we pursue high quality, to provide customers with high quality bearings.

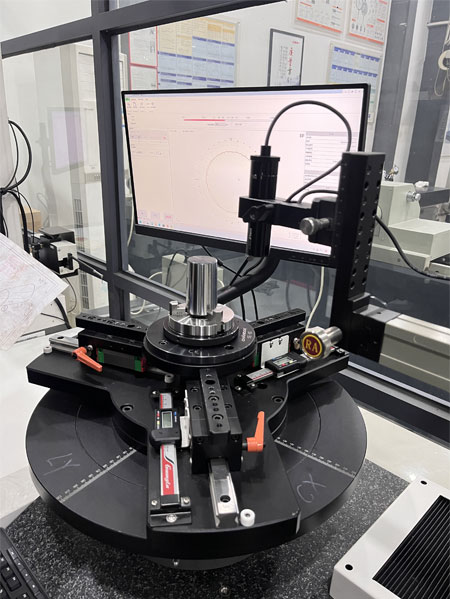

Therefore, ZWA sets up a measurement and testing center and uses the most advanced measuring instruments, such as spectroscopy analyzer, hardness, roughness, roundness profile tester and dimensional measuring tools to collect parameters such as bearing dimensions, vibration, bearing clearance and bearing contact angle to judge the running state of the bearing and whether it meets the standard to ensure the precision production of the bearing.

Each batch of bearings has a detailed test report before leaving the factory,which is the guarantee of ZWA high-quality bearings,one of China’s quality bearing manufacturers.

It ensures that the parts have perfect dimensional accuracy and positional accuracy.

It ensures that the parts have lower vibration and noise.

It ensures the accuracy of the macroscopic and microscopic structures of the parts.

It ensures that the surface quality of the bearing meets the design requirements, thereby guaranteeing its wear resistance, lubrication performance, and operational accuracy.

These precision bearing measuring instruments that are the key guardians of quality. It strictly controls the dimensional tolerance and rotational accuracy of bearings, ensuring that each product of ZWA is qualified and reliable, directly improving the qualification rate and service life.