High Quality Ball Bearings

Ball bearings are a part of rolling bearings. As a professional bearing supplier and one of the ball bearing manufacturers in China, ZWA has its own ball bearing factory and the business covers home and abroad. Compared with roller bearings, ball bearings are point contact which makes the obstruction is small, and the contact section is oval. Ball bearings are composed of an inner ring, outer ring, cage or retainer, and balls. The balls are mounted between the inner ring and outer ring. This kind of bearings allows for smooth, high-speed motion, reduced friction, and both axial & radial load capacity. The main function of ball bearings is to confirm the relative position of two parts ( usually shaft and housing), make them rotate freely, and transmit the loads in between. Especially in those high rotating speed conditions, the function can be expanded to free rotating without abrasion. Ball bearing manufacturers in China play a crucial role in the global supply chain for these components.

Different Types of Ball Bearings and Their Uses

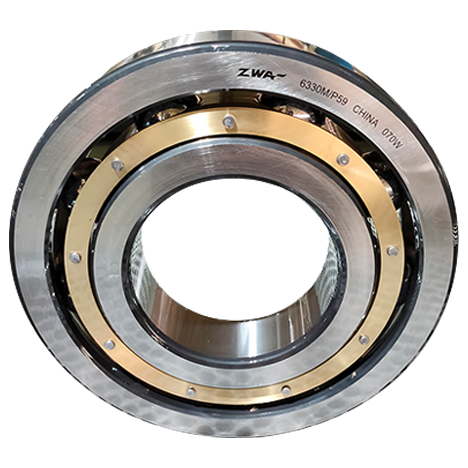

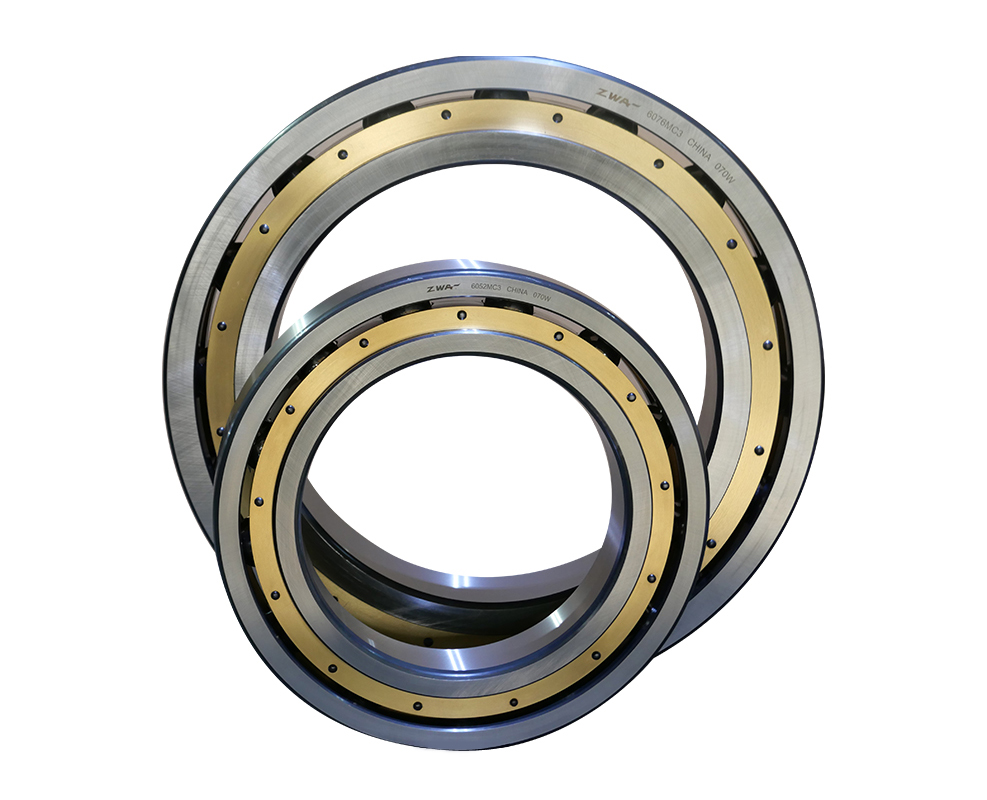

In general, ZWA's steel ball bearings for sale use chrome steel and cage can be steel one or brass one. The balls are usually steeled ones, too. ZWA's ball bearings include deep groove ball bearings, angular contact ball bearings and thrust ball bearings with multiple bearing rows. Leam more about our ball bearings of different diameters with diferent numbers.

With deep groove ball bearing factory, ZWA' s products include single row and double row ones. For the single row deep groove ball bearings which are also the most widely used type, ZWA offer it with both capped and open. For the capped ones, it includes anti-rust design and anti-oil design. For the anti-dust design, the bearings are with pressed steel cap. And for the anti-oil design, the bearings are with seals to prevent lubrication leaking from inside.For the double row deep groove ball bearings, while there is deviation of alignment between the inner ring and outer ring, extra load will occur which will cause extra loads to the balls and cages. In this case, the service life of the bearing will reduced. Therefore, the max allowable deviation is only 2 arc minute. Any bigger deviation will increase the noise level.

In the past years, ZWA has offered hundreds pieces of deep groove ball bearings, especially single-row ones to the customers. With higher precision and excellent performance of the bearings, ZWA has favored the customers to reduce the cost, increase the productivity and prolong the service life of the equipment.

-

Deep groove ball bearings are made of

Basic China deep groove ball bearing is made up of one inner ring, one outer ring, one cage and a group of balls. It can bear both radial and axial load capacity.

-

Features of deep groove ball bearings

Bearing both radial and axial loads

Lower friction

Higher rotating speed

A kind of self-alignment function

-

Use and Application of deep groove ball bearings

As the most widely used bearings, deep groove ball bearings appear in almost every industry, especially in agricultural, construction industry and automobiles

Angular Contact Ball Bearings Size PDF

Angular Contact Ball Bearings Size PDF

-

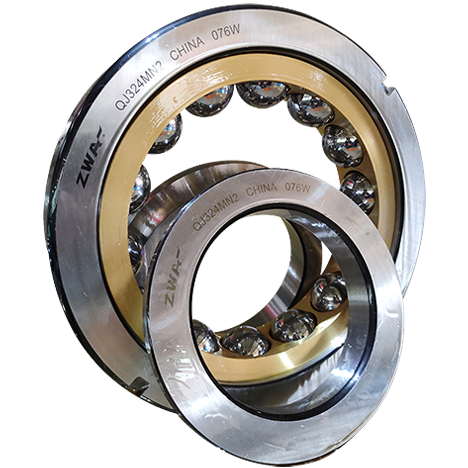

Feature of angular contact ball bearings

Bear higher radial loads

Bear combined radial and axial loads

Bear higher rotating speed

Special design on the raceways of inner ring and outer ring

-

Use and Application of angular contact ball bearings

Angular contact ball bearings are designed for high-speed and high precision applications, like compressor, chemical industry, main spindle of tooling machine, gearbox, pumps, agriculture etc.

-

Angular contact ball bearings made of

Based on different contact angle, angular contact ball bearings can be divided into 70000C type (α=15°), 70000AC type (α=25°), 70000B type (α=40°). Usually, for higher precision and higher rotating speed, the contact angel is 15°.

Based on different match method, ZWA’s angular contact ball bearings can be divided into back to back paired 70000 C(AC, B) DB type, face to face paired 70000C(AC, B)DF type and four point angular contact bearings (QJ0000).

Single-row angular contact ball bearings can only bear axial load from one direction and limit the axle or shaft make replacement in only one axial direction. If in case of accommodating radial load, extra axial load will occur.

Double row angular contact ball bearings can bear combined axial and radial loads in which radial loads are higher.

For the paired angular contact ball bearings, while mounting the pair, the wide surface should match the wide ones, narrow surface with the narrow one. For further details, please contact ZWA.

-

Thrust ball bearings made of

Thrust ball bearing is composed by housing ring, shaft ring, cage and balls. The ring match with the shaft is called shaft ring and the one matched with the housing is called housing ring. Those parts are separable and assembled on the shaft while in application. This kind of bearing can only bear axial load not subjected to any radial load. If in high speed application, oil lubrication is a must.

-

Features of thrust ball bearings

Separable and interchangeable due to inner design

Bear the original misalignment

Bear high axial load capacity

Interference fit allowed

-

Use and Application of thrust ball bearings

Metals, pumps, hook of crane, centrifuge, reducers, mining and cement.

ZWA is looking for distributors all over the world. If you are a quality-oriented distributor, if you suffer from long term delivery and after-sale service, if you want to increase the profit, contact us. ZWA bearings live up your expectations.

Ball Bearing Construction

Ball bearings is kind of rolling bearings. They allow very high rotating speed.

The following four parts usually constitute the ball bearing construction:

Outer ring: it in general does not move in case of rolling.

Inner ring: it rotates with the shaft.

Balls: they are mounted between the inner and outer rings, enable the movement between them.

Cages: they are holders for the balls to retain them in the right positions. Usually they are made of brass or steel.

Shields or seals: they are mainly functioned to prevent contaminant. Those bearings are well-lubricated with grease ex work.