Tapered roller bearings, with their unique structural design and excellent performance, play a crucial role in the complex operating systems of modern industry. From the roar of heavy machinery to the speed of high-speed trains, its presence is everywhere. This article will delve into its structural mysteries, performance advantages, and wide range of application scenarios.

The core design concept of tapered roller bearings lies in their tapered geometric structure, which brings significant engineering advantages:

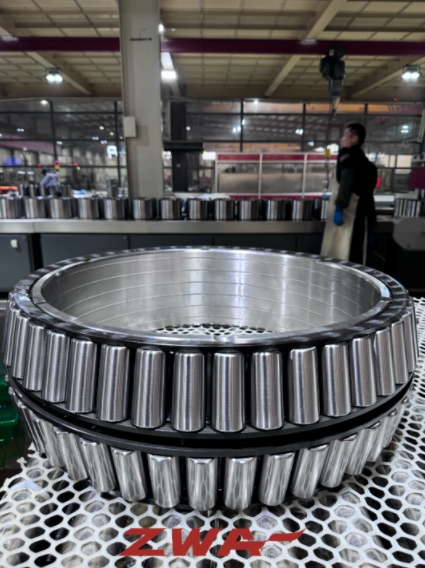

● Conical roller and raceway: The roller and the inner and outer raceway are designed in a conical shape, so that the extension line of the roller bus bar intersects at a point on the bearing axis, forming an ideal contact state of pure rolling and greatly reducing friction loss.

● Separable design: The inner ring, rollers, and cage components can usually be separated from the outer ring as a whole (inner component), simplifying installation and maintenance, especially suitable for situations that require frequent disassembly and assembly.

● Edge guide: The inner ring's large edge precisely guides and supports the large end face of the roller, effectively preventing the roller from tilting and sliding, ensuring stable load transmission.

● Function of the cage: The cage accurately separates the rollers, maintains uniform spacing, prevents collisions, ensures smooth operation, and reduces wear.

The unique structure endows tapered roller bearings with a series of outstanding performance:

● Extraordinary carrying capacity:

○ Radial and axial composite bearing: capable of withstanding significant radial and unidirectional axial loads simultaneously, it is the preferred choice for composite load conditions.

○ High rigidity: By precise pre tightening, the system rigidity can be significantly improved, vibration and deformation can be suppressed, and equipment accuracy can be enhanced.

● Excellent service life:

○ Optimize stress distribution: The conical structure makes the contact stress more evenly distributed along the length of the roller, delaying fatigue peeling.

○ Pure rolling advantage: significantly reduces harmful sliding friction, reduces wear and temperature rise, and extends the service life of bearings.

● Flexible pre tightening and adjustment:

○ Adjustable clearance/preload: By adjusting the axial relative position of the inner and outer rings during installation, the operating clearance or preload can be accurately set to optimize performance.

● Adjustment compensation ability:

○ Partial designs, such as those with convex rollers or special raceways, allow for limited angle centering to compensate for slight alignment errors between the shaft and bearing seat.

With the above advantages, tapered roller bearings are widely used in many key fields:

● Heavy Machinery and Engineering Equipment - Responsibility for Strength:

○ Mining machinery (crushers, ball mills): withstand extreme impacts and heavy loads.

○ Construction machinery (excavators, loaders): Dealing with huge overturning moments and vibrations in slewing supports and walking mechanisms.

○ Metallurgical equipment (rolling mill): supporting rolling rolls, capable of withstanding ultra-high rolling forces and thermal deformation challenges.

○ Large gearboxes (wind power, ships): transmit megawatt level torque and withstand complex loads.

● Railway Transportation - Guardians of Speed and Stability:

○ Traction motor: supports the rotor and transmits strong traction force.

● Agricultural machinery - resilient operation in the fields:

○ Tractors and harvesters: support transmission systems, walking mechanisms, and agricultural machinery under harsh working conditions (dust, impact, heavy loads).

● Wind power generation - a reliable pillar of green energy:

○ Gearbox: Used in key positions such as high-speed stages, it efficiently transmits large torque converted from wind energy and is the core of long-term reliable operation of wind turbines.