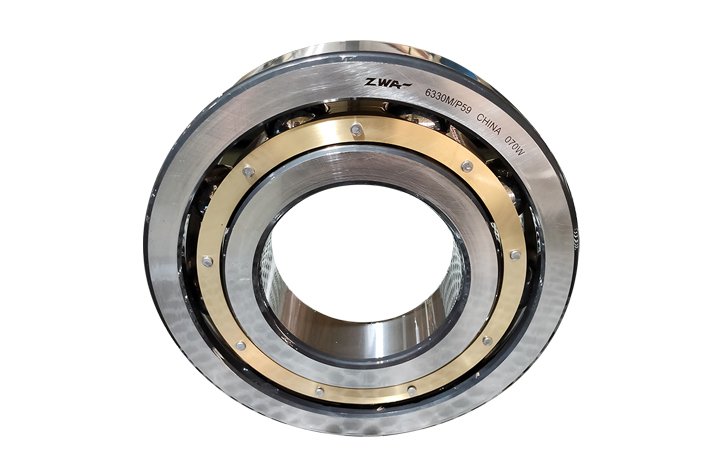

Deep groove ball bearings, also known as DGBB, are the typical rolling bearings that have the widest application. ZWA Bearings, as a professional deep groove ball bearing manufacturer and exporter, produces basic China deep groove ball bearings made up of one inner ring, one outer ring, one cage, and a group of balls. These bearings can bear both radial and axial load capacity, making them suitable for working conditions with higher rotating speeds, and lower noise, and vibration levels. Additionally, this kind of bearing is easy to mount or dismount and requires less maintenance and inspection.