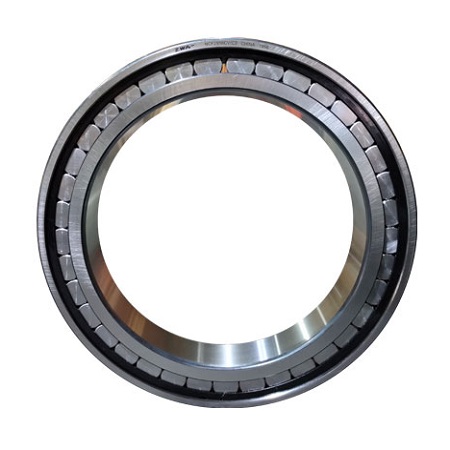

Single row cylindrical roller bearings are the most common type of cylindrical roller bearings. They have a relatively simple structure and are suitable for applications that bear unidirectional radial loads. Their main features and advantages include:

High load-carrying capacity: The single-row design of cylindrical roller bearings effectively distributes the load over a large contact area, resulting in strong load-carrying capacity. Compared to ball bearings, roller bearings can withstand higher radial loads and have a lower friction coefficient.

Low friction and high speed: These bearings can provide smooth support at high operating speeds, making them widely used in machinery that requires high-speed operation, such as motors and fans.

Easy installation and maintenance: The simple design of single-row bearings makes installation and removal relatively easy, and maintenance costs are low, making them suitable for simpler mechanical systems.

Overall, single row cylindrical roller bearings are suitable for applications that bear large radial loads but no significant axial loads, such as automotive wheel axles, electric tools, and agricultural machinery.

Compared to single-row bearings, double row cylindrical roller bearings have an additional row of rollers, providing stronger load-carrying capacity and higher rigidity. Their main features and advantages are highlighted in the following aspects:

Double load-carrying capacity: The double-row design allows the bearing to simultaneously withstand larger radial loads and certain axial loads, making them suitable for more demanding conditions, especially in situations with heavy load and impact load.

High adaptability: Because double-row cylindrical roller bearings can simultaneously bear loads from multiple directions, they are widely used in machinery that needs to withstand multi-directional loads, such as wind turbines and heavy machinery equipment.

Higher rigidity and stability: Double-row bearings offer higher rigidity and stability, performing excellently in situations that require high structural rigidity and bearing support stability, such as in the steel and mining industries.

Therefore, double row cylindrical roller bearings are suitable for heavy equipment and machinery that requires high load and high rigidity support, such as large gearboxes, rolling mills, and mining machinery.

Four row cylindrical roller bearings are the type with the highest load-carrying capacity among cylindrical roller bearings, typically used in extremely high-load scenarios. Their main features and advantages include:

Extremely high load-carrying capacity: The four-row roller design allows the bearing to distribute loads from all directions, especially radial loads, providing significant advantages in heavy load, impact load, and high-temperature and high-pressure environments.

Suitable for large equipment: Due to their higher rigidity and load-carrying capacity, four-row bearings are widely used in large machinery, heavy machinery, and high-load operating conditions, such as in metallurgy, mining, paper-making, and shipbuilding industries.

Good operational stability: Four-row cylindrical roller bearing provides more stable support, reducing vibration and noise, allowing equipment to run stably for extended periods.

Easy maintenance and replacement: Although the four-row design is complex, compared to other large bearings, four-row bearings still offer relatively simple maintenance and replacement methods.

Four row cylindrical roller bearings are suitable for large equipment that needs to bear extremely high loads and run under high-intensity conditions, especially in high-load, heavy-load, and long-duration mechanical systems, such as steelmaking equipment, mining excavation machinery, and large gearboxes.

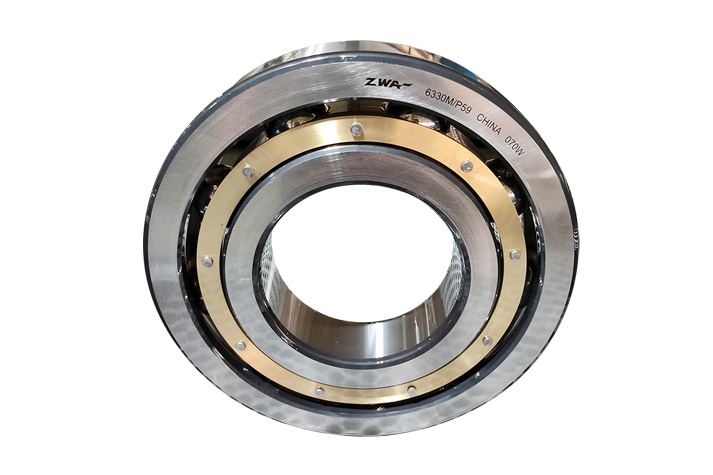

ZWA's single row cylindrical roller bearings are designed for high radial load capacity and moderate axial load, making them ideal for heavy machinery, tooling machines, reducers, automobiles, mining, and steel processing. These bearings feature separable inner and outer rings, enabling easy installation and maintenance with minimal tools. Engineered for harsh working conditions, they offer low friction, customizable configurations, and extended service life, ultimately reducing costs and improving equipment efficiency. ZWA provides options for cage materials, including pressed steel, machined brass, and polyamide, to ensure optimal durability and performance across various applications.

| Product Information | Details |

|---|---|

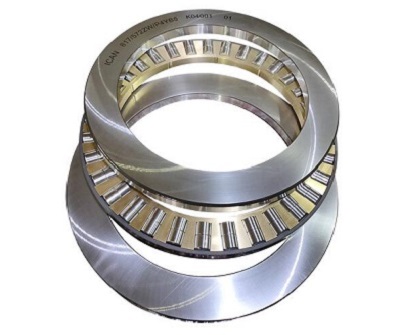

| Product Name | Double Row Cylindrical Roller Bearing |

| Manufacturer | ZWA Bearing, one of the leading China cylindrical roller bearing manufacturers |

| Types | NNU, NN, NNUP (based on flange and cage design) |

| Bore Types | Cylindrical bore, Tapered bore |

| Cage Materials | Machined brass, Steel |

| Features | Compact internal structure, Higher stiffness, Higher load capacity, Small deformation after high load, Lower friction, Longer service life, Improved operational reliability, Separable and interchangeable, High-speed ability |

| Load Capacity | Able to bear extremely higher load capacity than single-row, Vibration ratio decreases 70%, Wave ratio is one time higher than single-row |

| Applications | Spindle of tooling machine, Rolling mills, Gearboxes, Grinding machines |

| Benefits | Reduce cost, Increase productivity, Prolong equipment service life, Improve sustainability |

| Additional Resources | ZWA's CCJA Bearings - For vibration applications, ZWA Bearing using in Paper & Pulp |