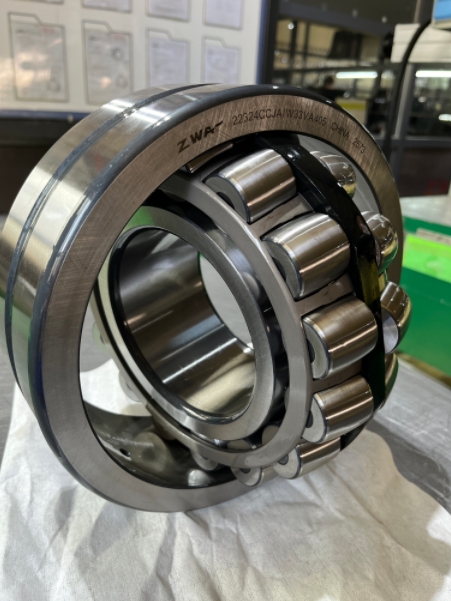

ZWA's CCJA type bearing is a spherical roller bearing specially designed for use in vibration applications. The unique construction of the bearing, including cylindrical and tapered holes, ensures stability and reliability in a variety of applications. It can adapt to the possible installation space in different equipments, providing adequate support. Ensure sufficient bearing capacity and service life.

With superior manufacturing processes and rigorous quality control, ZWA provides users with superior performance and durability.

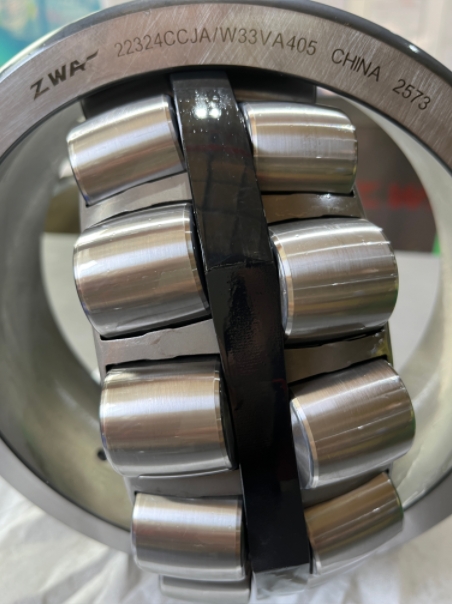

Symmetrical roller design:

The CCJA type typically features symmetrically arranged rollers, optimizing the load distribution. It can simultaneously withstand high radial loads and a certain amount of axial loads (bidirectional), making it suitable for heavy-duty working conditions.

Double-row rollers and spherical outer rings:

The spherical raceways on the outer ring work in conjunction with the double-row rollers on the inner ring to endow the bearing with an automatic self-aligning function (the self-aligning Angle is usually 1.5° to 3°), which can compensate for shaft bending or installation alignment errors.

Cage design:

Featuring lightweight and high strength, and is suitable for high-speed operation.

High load-bearing capacity

The double-row roller structure significantly enhances the radial load capacity of the bearing compared to ordinary ball bearings, making it suitable for heavy industrial fields such as mining machinery and rolling mills.

Anti-vibration and shock:

The line contact design between the rollers and the raceways disperses stress and enhances the impact resistance, making it suitable for working conditions with significant vibration.

Low friction and temperature rise:

The optimized roller profile and cage guidance method reduce friction, lower operating temperature and extend service life.

Typical scene:

Heavy-duty equipment that requires self-aligning, such as metallurgical rolling mills, mine crushers, large fans, papermaking machinery, and ship transmission systems.

Special environmental adaptability:

Through material upgrading (such as vacuum degassed steel) or coating, it can be applied in high-temperature and corrosive environments.