Mining machinery is mostly used in sparsely populated mountains, deserts and other areas. Mines are harsh battlefields where heavy loads, impacts, dust and moisture interweave. The crushers roar as they crush huge rocks, the conveyor belts carry long queues of heavy ores, and the elevators repeatedly rise and fall in deep Wells - these core devices are constantly undergoing extreme tests. The reliability of its power transmission and support system is directly related to production efficiency and safety. In this environment, any equipment failure, will affect the overall situation. This requires that the bearings used for mining machinery must be equipment with excellent durability and reliability. And cylindrical roller bearings are precisely the indispensable "solid backbone" among them.

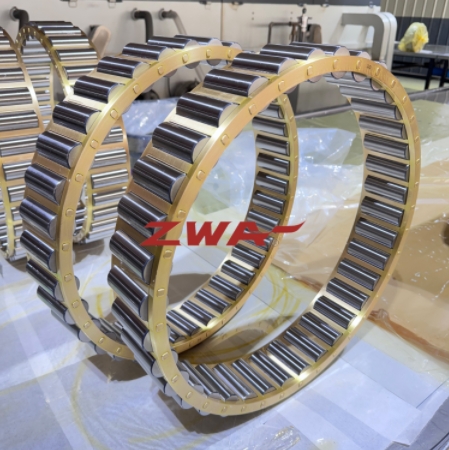

Cylindrical roller bearings produced by the Chinese bearing brand -ZWA, are with high toughness, high wear resistance, suitable for high speed, impact load conditions. At the same time in the internal design corresponding to different working conditions for special design, extend the service life of the bearing and improve the use of reliability, in order to meet the customer's customized needs.

The winning formula for cylindrical roller bearings in mining:

Its linear contact roller design disperses the huge radial load on a longer contact line. Compared with point contact ball bearings, the load-carrying capacity can be increased several times, making it an ideal choice for supporting heavy-duty parts such as the main shaft, gearboxes, and rollers of mining equipment.

With a sturdy structure, it can effectively withstand the severe vibration and impact loads during the operation of mining equipment, maintain rotational accuracy, and reduce deformation.

Cylindrical roller bearings with specific cage and roller designs can meet the higher operating speed requirements in mining equipment.

It offers various structures such as NU (outer ring without flange), NJ (single flange), and NUP (single flange + flat flange). The NU type allows for a slight axial movement of the shaft relative to the bearing housing (thermal expansion compensation), while the NUP/NJ type can withstand a certain axial positioning force, meeting the complex installation requirements of mining equipment.

By using reinforced rollers, high-purity steel with special heat treatment processes, and an optimized internal geometric design, the fatigue life under heavy loads and polluted environments is significantly enhanced, typically reaching 3 to 5 times that of ordinary bearings. Advanced sealing technologies (such as contact lip seals and labyrinth seals) build a reliable defense line, effectively preventing dust and water vapor from entering.

Cylindrical roller bearings, with their powerful radial load-carrying capacity, rigidity, impact resistance and flexible design, have become the core guarantee for the power transmission and support systems of heavy mining equipment. Its outstanding reliability and long service life significantly reduce the equipment failure rate and maintenance costs, laying a solid operational foundation for the safe, continuous and efficient mining of mines. Amidst the roar of the mine, it is the key force that silently sustains the colossal entity and drives the pulse of wealth.