When your equipment is subjected to harsh radial loads and impacts, and stable operation and long service life become the core requirements, ZWA cylindrical roller bearings are your reliable and solid backing!

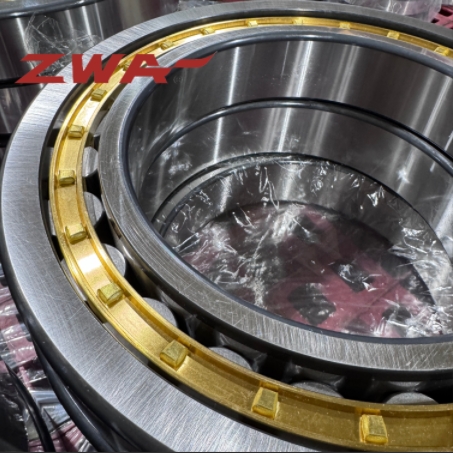

As a leader in the bearing industry for decades, ZWA is well aware of the severe challenges of heavy-duty working conditions. Our cylindrical roller bearings are made of selected high-strength alloy steel, which is precision forged and quenched through advanced heat treatment processes, endowing the rollers and raceways with extraordinary hardness and toughness. The optimized internal design maximizes the contact area between the rollers and the raceway, achieving excellent radial load capacity and easily handling extreme pressures in fields such as metallurgy, mining, and heavy-duty transportation.

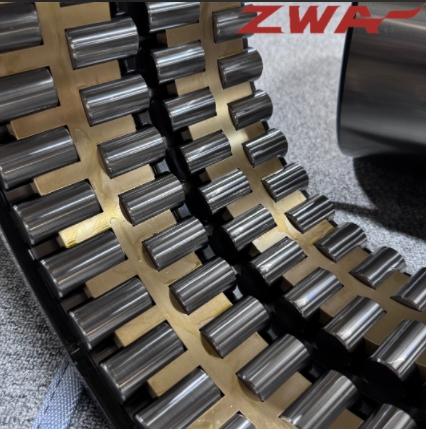

ZWA bearings are manufactured with micrometer level precision as the core. High precision roller grouping matching and ultra precision grinding of the raceway surface ensure even load distribution and significantly reduce friction and temperature rise. Combined with strict screening of high-quality retaining frames and advanced lubrication technology, bearings operate more smoothly and quietly, with significantly extended service life, effectively reducing equipment failure rates and maintenance costs.

ZWA implements a rigorous quality control system that runs through the entire process from raw material entry to finished product delivery. Each set of bearings undergoes multiple precision inspections and life simulation tests to ensure stable and reliable performance, consistent quality, and provide solid support for your critical equipment.

Whether it is large gearboxes, heavy-duty rolling mills, or the core transmission of mining machinery and engineering equipment, ZWA cylindrical roller bearings have become a reliable cornerstone for driving efficient industrial operation with their strong load-bearing capacity, precise operation, and long-lasting endurance.