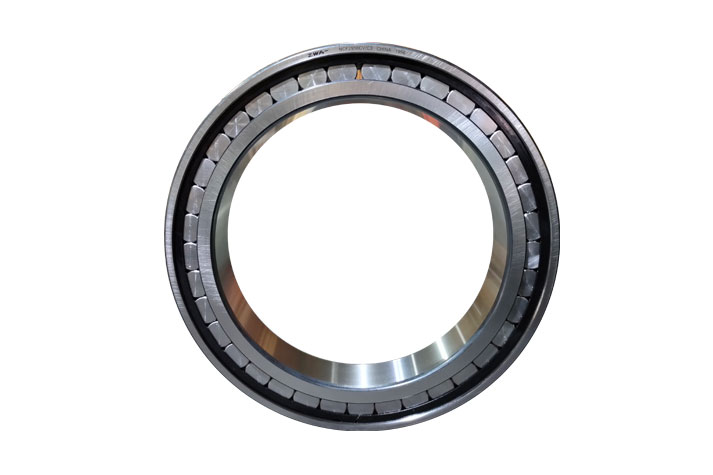

TRB bearings are separable bearings. Both the inner and outer rings of the bearing have tapered raceways. These bearings are classified into different structural types such as single-row, double-row, and four-row TRB bearings based on the number of roller rows installed. Single-row TRB bearings can withstand radial loads and unidirectional axial loads. When the bearing is subjected to a radial load, an axial force component is generated, thus requiring another bearing capable of withstanding the axial force in the opposite direction to balance it.

The angle of the outer ring and the diameter of the outer raceway of TRB bearings are standardized and specified according to the same dimensional parameters. Design and manufacturing modifications are not permitted. Therefore, the outer rings and internal components of TRB bearings are interchangeable worldwide.

TRB bearings are mainly used to withstand combined radial and axial loads that are primarily radial in nature. Compared to angular contact ball bearings, they have a higher load capacity but a lower limit speed. TRB bearings can withstand unidirectional axial loads and can limit the axial displacement of the shaft or housing in one direction.

Adjusting axial clearance. The installation of TRB bearings can utilize adjusting nuts, shims on the bearing journal, and threaded bores in the bearing housing to adjust axial play. Alternatively, a preloading spring can be used for adjustment. The size of the axial play is related to the bearing installation arrangement, the distance between bearings, and the materials of the shaft and bearing housing, and should be determined based on operational conditions.

For high-load, high-speed TRB bearings, the effect of temperature rise on axial play must be considered when adjusting the clearance. The reduction in clearance due to temperature rise should be estimated, and the axial play should be adjusted accordingly.

For low-speed, low-vibration bearings, no-clearance or preloaded installation should be adopted. The purpose is to ensure good contact between the rollers and raceways of the TRB bearings, evenly distribute the load, and prevent damage to the rollers and raceways due to vibration and impact. After adjustment, the axial clearance should be checked using a dial gauge.