Split roller bearing is one of the common and important parts in mechanical equipment, which plays a key role in the normal operation and life of the equipment. In order to ensure the reliability of the split roller bearing and extend its service life, proper maintenance and repair is essential.

According to different application scenarios and working conditions, you can choose grease or lubricant for split roller bearing lubrication. Grease is suitable for low-speed and high-load working conditions, and can provide good sealing and anti-impact performance. Lubricants are suitable for high speed split roller bearings and high temperature environments.

Split roller bearings are susceptible to dust, moisture and other contaminants in the working environment. When cleaning split roller bearing, appropriate cleaning agents and tools should be used, and care should be taken to avoid excessive cleaning and the use of improper cleaning methods. After cleaning, the split roller bearing should be thoroughly dried and coated with an appropriate amount of grease or lubricant before reassembly.

During installation, appropriate tools should be used to avoid excessive impact and stress concentration. Before installing the split roller bearing, the seat holes and the surface of the split roller bearing should be cleaned and inspected to ensure that they are smooth and undamaged. When disassembling the split roller bearing, record the relevant parameters and precautions for reference when reinstalling.

Before storage, the split roller bearing should be cleaned and lubricated, and protected with a rust inhibitor. Split roller bearings should be stored in a dry, clean and non-corrosive gas-free environment, away from direct sunlight and high temperatures. Regularly check the storage conditions and status of the split roller bearing to ensure that it is in good condition.

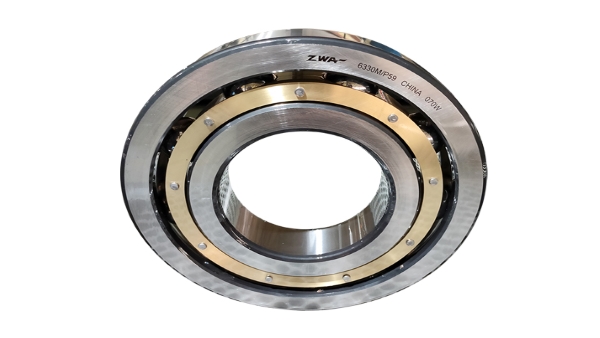

Dalian Guangyang Bearing Co., Ltd is a professional bearing manufacturer with trademark of ZWA.The major products of ZWA are spherical, cylindrical, tapered and split bearings. In the past 15 years, ZWA Bearings was devoted to the research & development of bearings applied in steel, mining, cement and paper-making. Targetting at high-end customers, ZWA has become suppliers of many world famous companies.