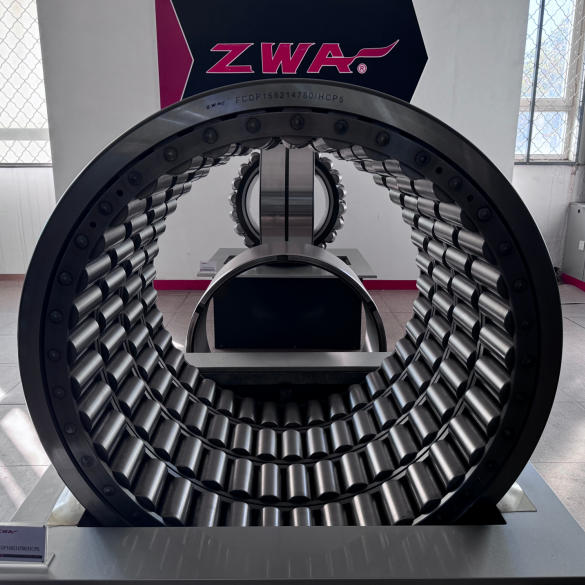

In the core of steel production - the rolling workshop, equipment needs to withstand extreme heavy loads, impact loads, and harsh environments. As the "key joint" of the rolling mill, the performance of bearings directly determines production efficiency, equipment stability, and operating costs. We are well aware of this challenge and have designed and manufactured high-performance four row cylindrical roller bearings and four row tapered roller bearings specifically for steel mill customers, providing solid and reliable support for your rolling mill.

Compared to standard bearings, four row bearings achieve extremely high radial and axial load carrying capacity by integrating four bearing raceway units into a compact race. This design perfectly meets the strict requirements of high rigidity, high load capacity, and limited installation space for the rolling mill roll neck, making it an ideal choice for supporting the rolling mill rolls and ensuring precise rolling.

1. Four row cylindrical roller bearings - excellent radial load experts

Features: This bearing is known for its extremely high radial load capacity and high-speed performance. Due to its detachable design (inner and outer rings can be separated), installation and disassembly are very simple, greatly reducing maintenance time and costs.

Advantage application:

Very suitable for supporting rollers (back support bearings) in rolling mills.

Mainly used to withstand huge radial loads, while axial loads are borne by independent thrust bearings.

Low friction coefficient is beneficial for reducing energy consumption and temperature rise.

Our added value: We use high-quality casehardened steel materials and perform precise grinding and optimized contour design on rollers and raceways, significantly improving fatigue life and effectively resisting impact loads and micro motion wear.

2. Four row tapered roller bearings - versatile radial and axial load combination

Features: Tapered roller bearings inherently have the ability to withstand large radial and axial loads simultaneously. The four row design amplifies this advantage and provides unparalleled rigidity stability.

Advantage application:

It is a classic choice for work roll bearing seats, especially on rolling mills that require frequent roll changes.

It is crucial to be able to withstand the bi-directional axial force generated during the rolling process, ensure the precise positioning of the rolling mill, and control the thickness and shape of the sheet metal.

The built-in pre tensioning clearance is adjustable, making it easy to optimize bearing configuration for optimal performance.

Our added value: Our advanced internal geometric design and surface treatment technology ensure that the load is evenly distributed among the four rows of rollers, preventing eccentric load and extending the bearing life. The special cage design ensures stability and lubrication effectiveness during high-speed operation.

Characteristics | Four-row cylindrical roller bearings | Four-row tapered roller bearings |

Main load | High radial load | Composite radial and axial load

|

Installation and maintenance | Relatively simple, and the inner/outer rings can be separated | Requiring more precise clearance adjustment |

High system stiffness | High radial stiffness | Extremely high radial and axial stiffness |

Typical application | Rolling mill support roll | Working roll of rolling mill |

If your device has independent thrust bearings to bear axial force, four row cylindrical roller bearings are an economical and efficient choice. If the bearing needs to handle both radial and axial forces simultaneously, four row tapered roller bearings are a more integrated and powerful solution.

Beyond the product itself: the complete solution we provide

What we offer is not just bearings, but a partnership to enhance the overall performance of your rolling mill:

Professional selection support

Accurate dimensions and tolerances

Reliable lubrication and sealing

Timely global supply

Let our four row roller bearing solution become your secret weapon for improving rolling mill efficiency, reducing downtime, and overall operating costs.