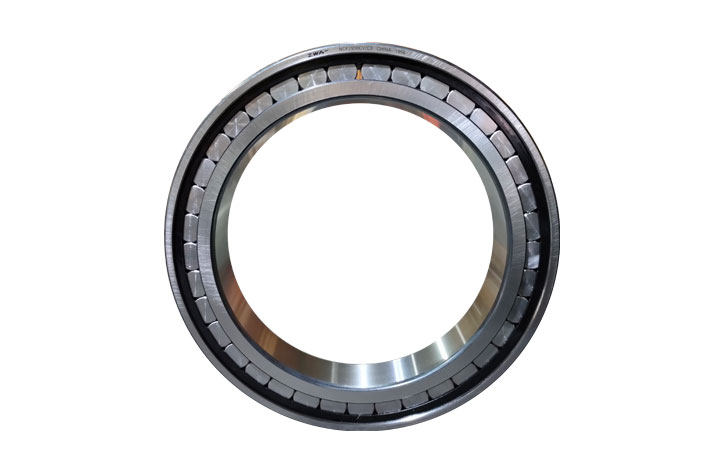

Cylindrical roller bearings are precision components widely used in various industrial applications. To ensure their optimal performance and longevity, it's crucial to follow specific handling, installation, and maintenance practices. Below are four key considerations for using cylindrical roller bearings effectively.

Cylindrical roller bearings are sensitive to contaminants and physical damage. To maintain their integrity:

Keep bearings clean: Store them in their original packaging until installation to prevent exposure to dirt and moisture.

Use appropriate tools: Employ proper lifting and handling equipment to avoid shock or impact damage.

Wear gloves: Handling bearings with clean hands or gloves prevents corrosion caused by oils or moisture from skin contact.

Store in a controlled environment: Keep bearings in a dry, clean area to avoid rust and contamination.

Improper installation can lead to premature bearing failure. To ensure correct installation:

Align components properly: Ensure that the shaft, housing, and bearing are correctly aligned to prevent misalignment stresses.

Apply even pressure: Use tools designed for bearing installation to apply uniform pressure, avoiding direct blows that can cause damage.

Check fit and clearance: Verify that the bearing fits correctly within the housing and on the shaft, with appropriate radial and axial clearances.

Lubricate adequately: Apply the recommended type and amount of lubricant to reduce friction and wear.

Routine maintenance is essential to detect and address potential issues early:

Monitor operating conditions: Regularly check for unusual noise, vibration, or temperature changes, which may indicate problems.

Inspect for wear: Periodically disassemble and inspect bearings for signs of wear, corrosion, or damage.

Lubrication management: Ensure that bearings are properly lubricated, and replace lubricant as per manufacturer recommendations to maintain optimal performance.

Clean bearings properly: When cleaning bearings, use appropriate solvents and methods to avoid introducing contaminants.

Contaminants and excessive loads can significantly reduce bearing life:

Seal bearings properly: Use seals or shields to protect bearings from dust, dirt, and moisture.

Avoid overloading: Ensure that the bearing is not subjected to loads exceeding its rated capacity, as this can lead to premature failure.

Control operating environment: Maintain a clean operating environment to minimize the ingress of contaminants.

| Precaution Area | Key Considerations |

|---|---|

| Handling and Storage | Keep bearings clean, use appropriate tools, wear gloves, store in a controlled environment |

| Installation Practices | Align components, apply even pressure, check fit and clearance, lubricate adequately |

| Maintenance and Inspection | Monitor operating conditions, inspect for wear, manage lubrication, clean properly |

| Contamination and Overloading | Seal bearings, avoid overloading, control operating environment |

By adhering to these precautions, you can enhance the performance and extend the service life of cylindrical roller bearings in your applications.