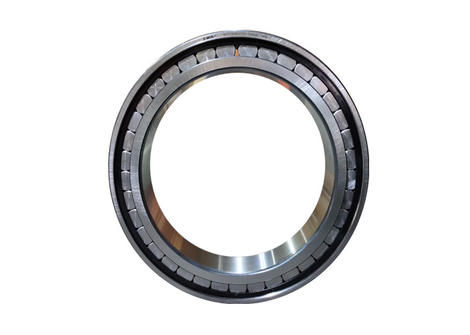

A double row cylindrical roller bearing consists of two rows of cylindrical rollers arranged parallel within a single bearing unit. This configuration increases the radial load capacity and enhances stiffness compared to a single-row design. The bearing provides high precision and is capable of operating at high speeds due to reduced friction between the rolling elements and raceways. It is typically used where both radial load demands and rotational accuracy are critical.

The double row cylindrical roller bearing is widely applied in heavy-duty and high-precision industrial environments. Its ability to carry large radial loads makes it ideal for applications where axial loads are minimal or supported by other components.

Typical applications include:

| Application Area | Reason for Using Double Row Cylindrical Roller Bearing |

|---|---|

| Gearboxes | High radial load capacity and dimensional stability |

| Rolling Mills | Handles heavy radial forces under extreme conditions |

| Machine Tool Spindles | High speed and precision for rotational accuracy |

| Steel Industry Equipment | Excellent resistance to deformation under fluctuating loads |

The double row cylindrical roller bearing performs exceptionally well under high-load and high-speed conditions. In machine tools, it ensures accurate shaft positioning and minimal deflection. In gear drives, the bearing accommodates varying operational speeds while maintaining structural rigidity. Its full complement or cage-guided roller design can be chosen depending on whether load capacity or speed is the priority.

When selecting a double row cylindrical roller bearing, several factors must be taken into account:

Radial Load Requirements: Ideal for very high radial forces; axial support must be externally managed.

Speed Conditions: Caged versions offer better high-speed performance; full complement versions suit slower, high-load operations.

Operating Temperature and Lubrication: Ensure proper lubrication type and sealing design for long service life.

Precision Needs: Often used in applications requiring fine tolerances and minimal vibration.

In conclusion, the double row cylindrical roller bearing is an essential component in industries requiring robust radial load support, rotational accuracy, and operational reliability. Its design flexibility and strong performance characteristics make it suitable for demanding mechanical systems across multiple sectors.