In industrial machinery, spherical roller bearings play an irreplaceable role as key components with high load-bearing capacity and strong adaptability. Based on structural differences, spherical roller bearings are classified into single row spherical roller bearings and double row spherical roller bearings. Each type offers unique advantages in different application scenarios. This article will explore their benefits in detail and provide selection guidance for engineers and maintenance personnel.

Single row spherical roller bearings, known for their simple structure, low friction, and relatively high rotational speed, are widely used in various high-speed rotating equipment. Their main advantages include:

With only one row of rollers, the overall size of the bearing is relatively small, making it suitable for space-constrained equipment. At the same time, it features low friction torque, allowing it to maintain low temperature rise during high-speed operation.

These bearings possess excellent self-aligning performance, automatically compensating for angular misalignment caused by installation errors or shaft deflection. This enhances system stability and extends service life.

The single row design allows for easier disassembly and installation, making it suitable for applications requiring frequent maintenance. Additionally, both manufacturing and replacement costs are relatively lower.

Therefore, single row spherical roller bearings are commonly used in motors, pumps, fans, and other equipment that operates at high speeds but under relatively light loads.

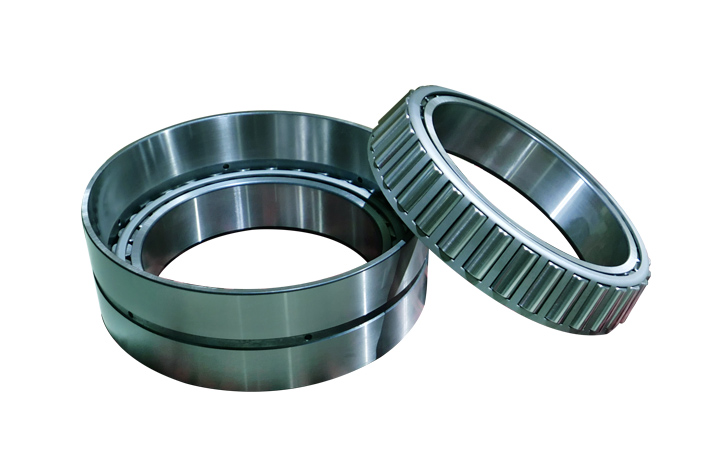

In contrast, double row spherical roller bearings offer significant advantages in load capacity and structural stability, making them widely used in heavy-load and high-impact machinery. Their benefits are reflected in the following aspects:

With a double row symmetrical roller arrangement, these bearings can support substantial radial loads and moderate bidirectional axial loads. This makes them especially suitable for heavy industrial equipment such as rolling mills and mining machinery.

The double row of rollers distributes load pressure more evenly, improving load uniformity. This enhances durability under impact loads, extends bearing life, and reduces failure rates.

The rigidity provided by the double row structure contributes to stable shaft system operation. This design demonstrates superior vibration resistance and reliability, particularly under high-speed and heavy-load conditions.

Thanks to their excellent load-bearing performance, double row spherical roller bearings are the preferred choice in high-strength, high-precision industrial applications.

While both single row and double row spherical roller bearings have their respective strengths, their usage scenarios and performance requirements do not completely overlap.

If the equipment demands higher speed and lighter loads, single row spherical roller bearings should be prioritized.

If load capacity and operational stability are more critical, double row spherical roller bearings offer a better solution.

In addition, proper lubrication methods, precise installation techniques, and regular maintenance checks are crucial to ensure the optimal performance of these bearings.

In the ongoing pursuit of mechanical efficiency and reliability in modern manufacturing and heavy industries, spherical roller bearings play an increasingly important role. A thorough understanding of the advantages of different structural types helps improve equipment performance, extend service life, and ultimately achieve stable and efficient operation of industrial systems.

| Category | Details |

|---|---|

| Product Name | Spherical Roller Bearings |

| Types | Single Row Spherical Roller Bearing sDouble Row Spherical Roller Bearings Thrust Spherical Roller Bearings |

| Features | Cost-effective with excellent performanc eLong lifespan using bainitic/martensitic treatment and premium steel High reliability with full roundness check and precision machining |

| Advantages | High load capacity (radial and axial) Accommodates misalignment Durable under heat, shock, and vibration Self-aligning to reduce stress Flexible in size and configuration Grease or oil lubrication Reduced friction and energy use |

| Applications | Heavy Machiner yIndustrial Gearboxes Steel & Metal Processing Pulp & Paper Industry Wind Turbines Mining & Quarrying Cement & Aggregates Marine & Offshore |

| Design & Manufacturing | Custom-designed to working conditions In-house machining with advanced testing/production systems Strict quality control |